Grinding & Polishing

Grinding is a machining process that employs an abrasive wheel as a cutting tool to remove material from a workpiece. This abrasive wheel, which contains grains of a hard, abrasive material such as aluminum oxide or silicon carbide, spins at high speeds and grinds away the surface of the workpiece to achieve the desired shape or finish. Grinding is used to produce a smooth finish on flat surfaces, and it’s also employed for more complex shapes such as those found in gears or other intricate parts. It’s particularly effective for hard materials that are difficult to shape with other cutting processes.

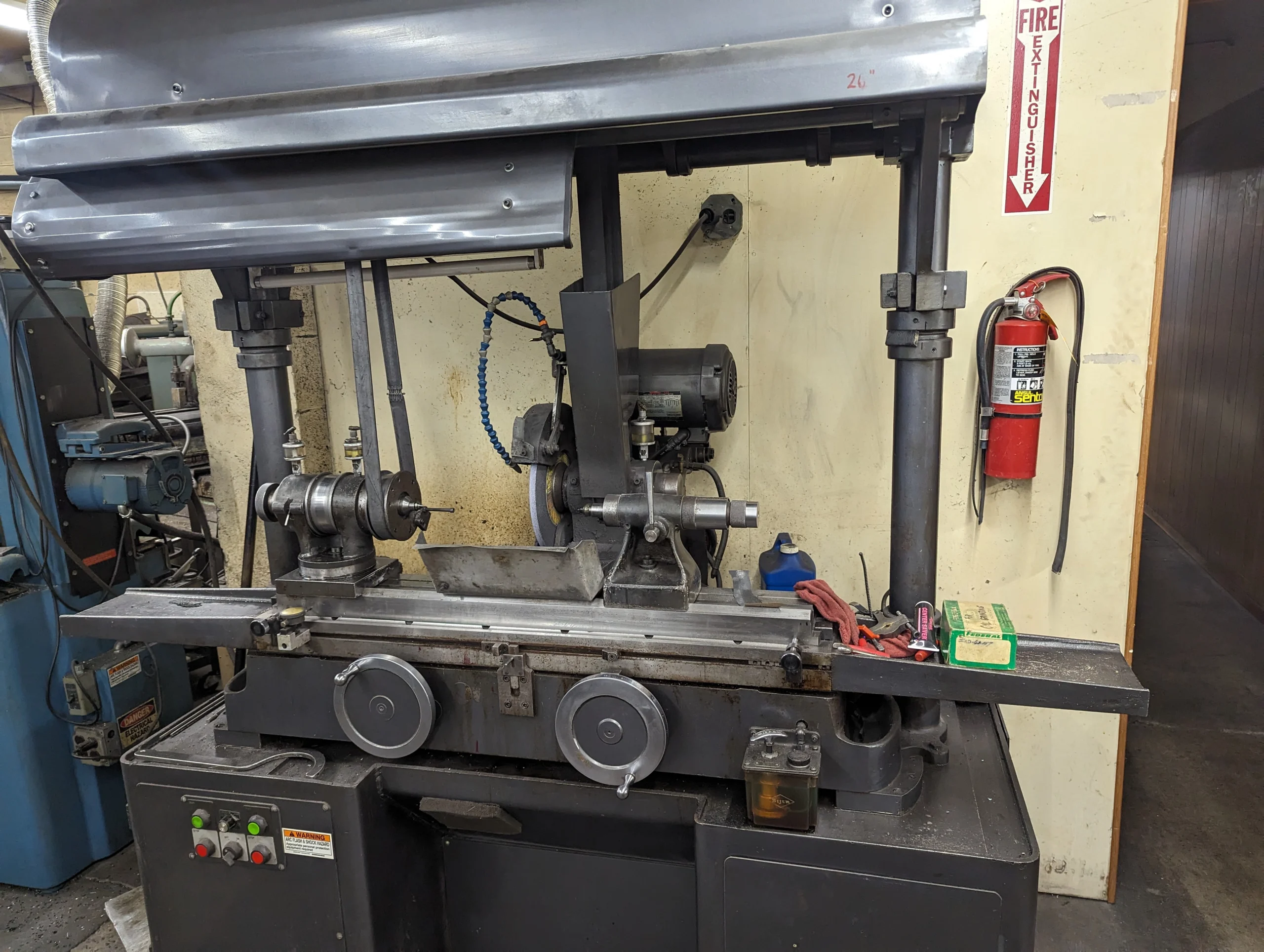

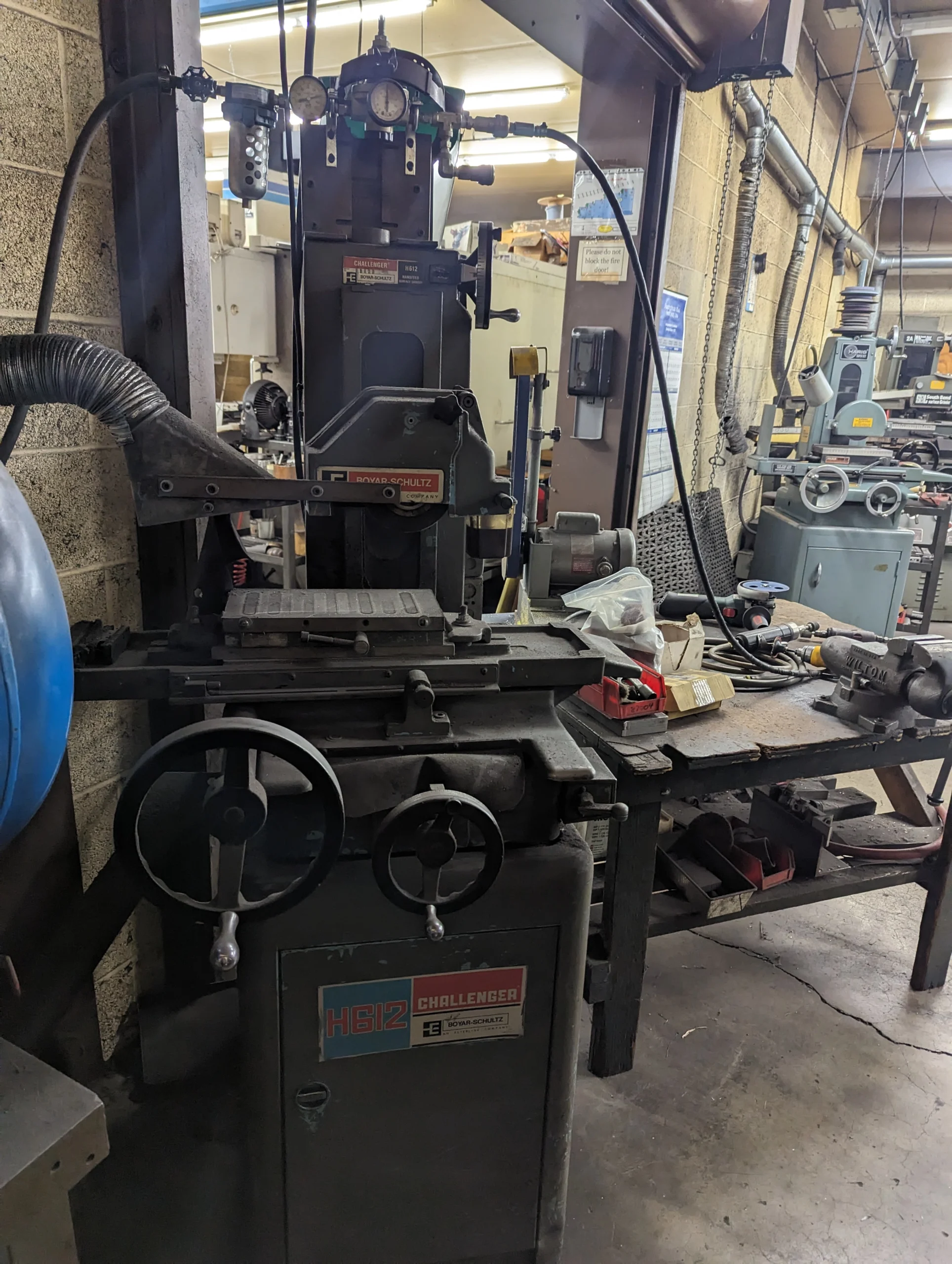

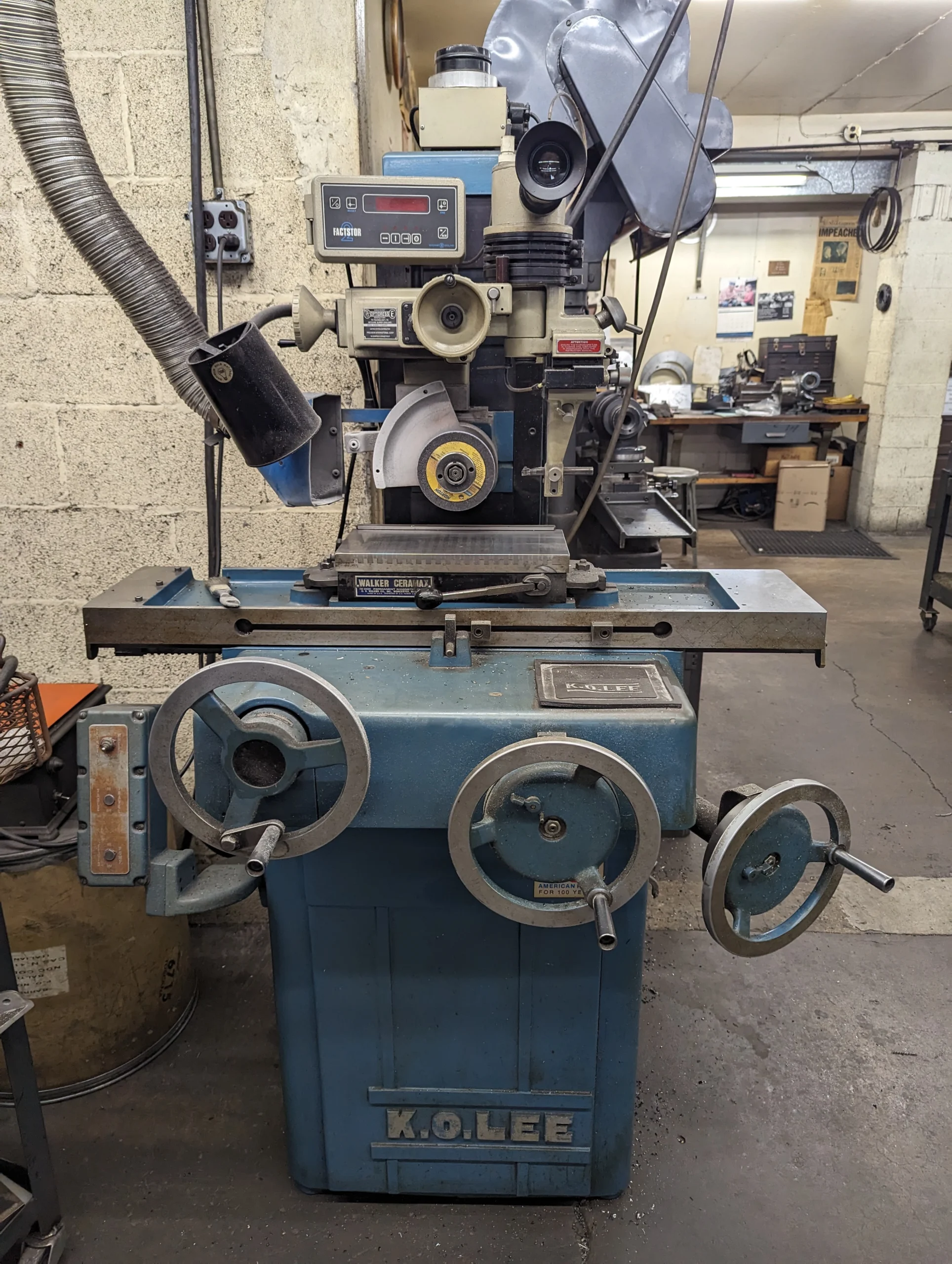

We have surface grinders, cylindrical grinders, as well as Blanchard grinders so that we can grind any hard material of any shape and size.

Polishing, on the other hand, is a finishing process that follows grinding. It involves using a softer wheel or a compound containing fine abrasive particles to create a high-quality finish with a high level of surface smoothness and minimal surface roughness. The objective of polishing is to achieve a mirror-like, reflective surface, free of scratches and imperfections. This is crucial in applications where surface finish is important, such as in optical devices, jewelry, and decorative metalwork.

Both grinding and polishing are essential steps in the manufacturing process, especially in metal fabrication and precision engineering. They contribute significantly to the functionality and aesthetics of the final product. The choice of abrasive material, wheel speed, and other parameters is critical in both processes to achieve the desired surface quality and dimensional accuracy.

equipment